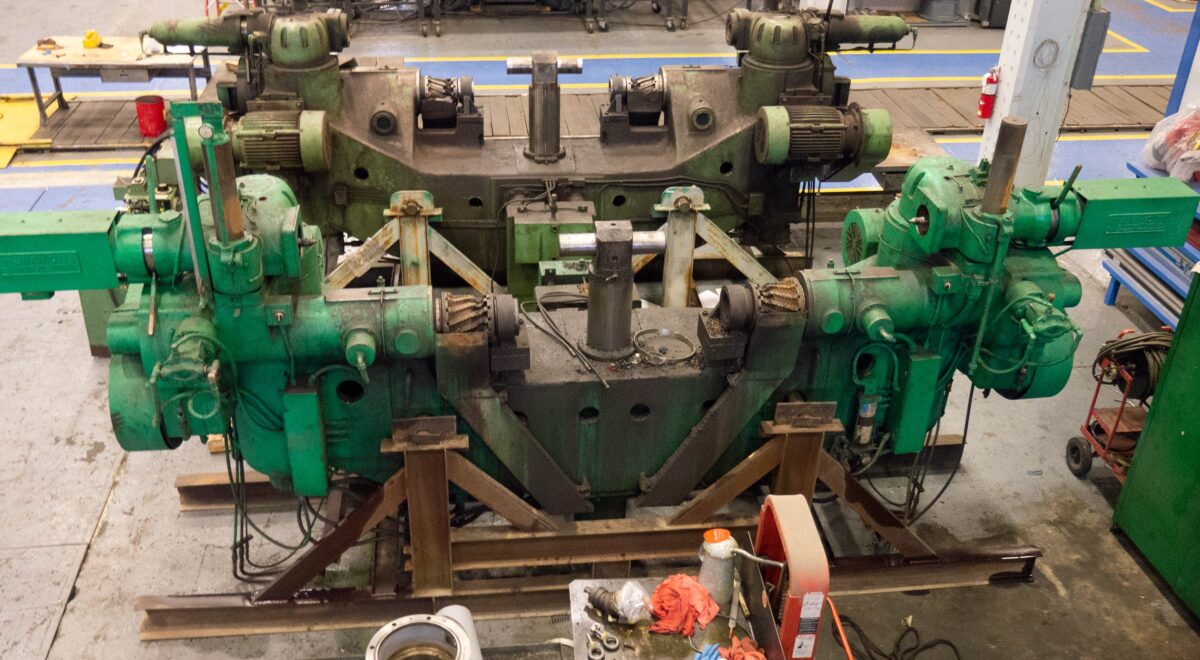

Stanray TN-84C Remanufactured Underfloor Wheel Truing Machine

The Stanray®‘s comprehensive remanufacturing program is made possible by our detailed records and drawings archive as well as decades of experience with the product line and interactions with Stanray customers around the world. NSH USA’s manufacturing and engineering teams regularly update and improve the machine, meaning full-profile milling process will manage extreme wheel wear condition and keep your rail vehicles safe and on track.

Upon receipt of an old machine, the unit is completely disassembled. All piping and wiring as well as worn parts are replaced. The steel castings are cleaned and inspected, built up by welding, and then completely re-machined to the latest OEM specifications. Purchased components as well as manufactured parts are thoroughly inspected. All new hydraulic valving, piping, and actuators as well as new electric motors, controls, and wiring are installed. Sub-assemblies are functionally checked, and the final assembly is factory and site tested to assure that it meets NSH USA’s and the customer’s expectations.

Machine Specifications

Download the Stanray TN-84C Remanufactured Underfloor Wheel Truing Machine product data sheet — for the full machine specification, please contact the Machine Sales team.

Production

Cycle time study available upon request

Diameter Accuracy

+/- 0.5 mm

Eccentricity

+/- 0.5 mm

Profile Accuracy

+/- 0.25 mm

Surface Finish

200 RMS axially, 150 RMS on wheel circumference

Milling Cutter Speed

200 RPM

Hydraulic Centering Ram Force

29.36 kN

Hydraulic Hold-Down Force

133 kN

Electrical Power

76 kW

Hydraulic Reservoir

340.69 liters

Maximum Wheel Diameter

1475 mm

Minimum Wheel Diameter

585 mm

Maximum Axle Load

445 kN

We're here to help

The NSH USA Customer Service Center (CSC) is here to support you and your machine. As the original equipment manufacturer (OEM), we are ideally suited to keep your machine productive and operating safely.