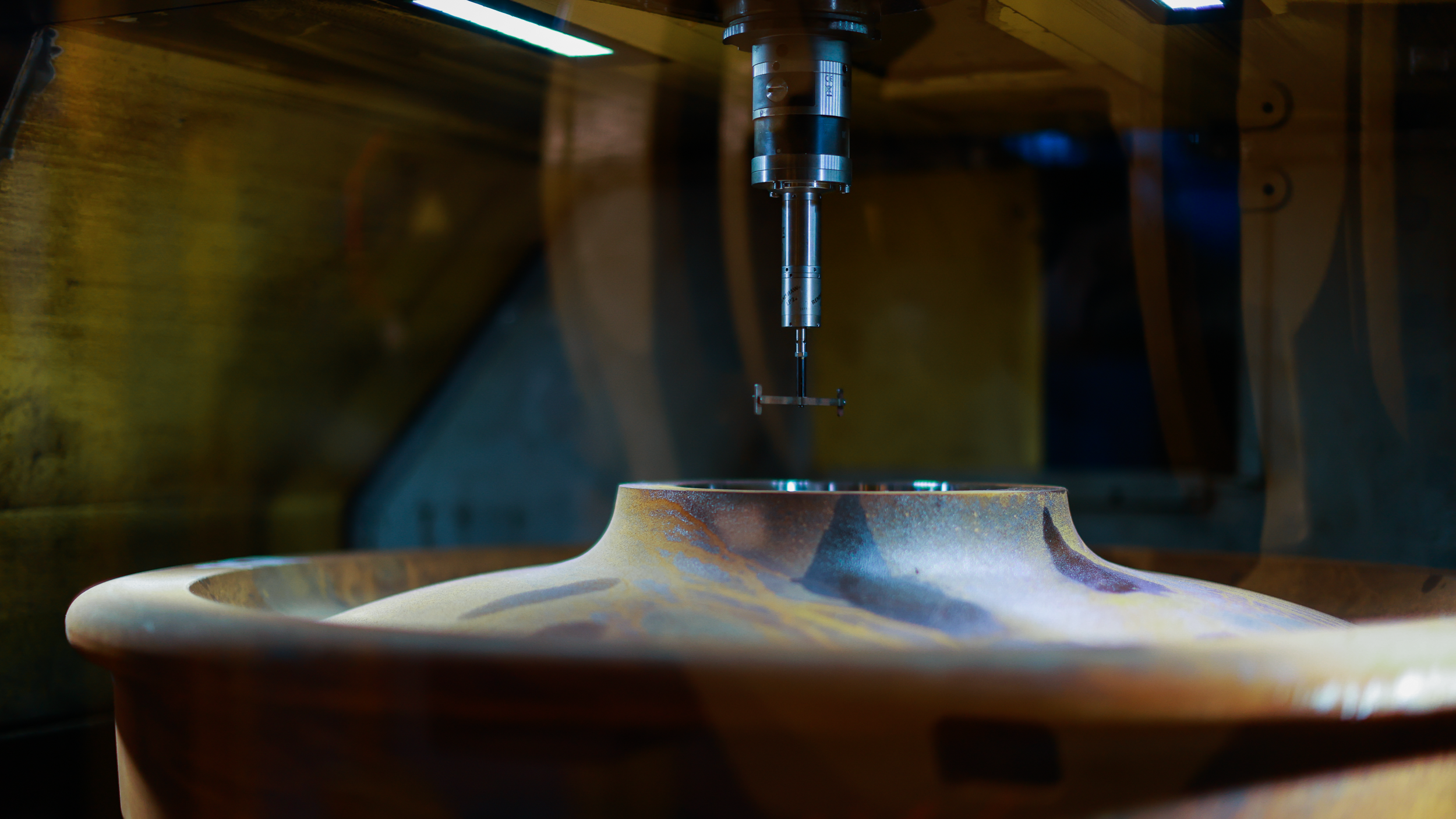

Simmons WTC-250 Wheel Turning Center

The Simmons WTC-250 Wheel Turning Center is a robust wheel boring machine for machining railway wheels in high production wheel shops. The machine structure consists of mineral polymer composite castings for maximum rigidity and vibration absorbing properties.

The bridge straddles the wheel while cutting for optimal stiffness. Front-to-back motion is achieved by dual ball screws and dual absolute linear encoders. The ram is carried in box ways and fitted with a heavy-duty quick change tool interface. An automatic tool changer provides for redundancy and increased productivity. Single point tooling supplies considerable flexibility. The integrated measurement system allows for pre-machining workpiece measuring and user-selectable degrees of post-machining part verification.

The WTC-250 is also available as an "mc" version that additionally provides live tooling for drill and tap and/or oil hole drilling, bringing those functionalities into one versatile machine.

The Siemens CNC control is provided with a NSH USA HMI utilizing railway wheel shop terminology, eliminating the need for operators to learn typical machine tool programming language. The system easily interfaces with other systems to receive wheel and axle information; it will additionally store production and dimensional results as desired.

Benefits of the WTC-250

High torque, shaft driven, geared table with constant surface speed capability

Wide range of wheel diameters automatically chucked without manually adjusting jaw tops

Full sheet metal guarding and maximized internal slops for exceptional chip management safety

Flexible configuration: the chip conveyor can exit front, back, left, or right - the HMI and power/control cabinet can additionally be located on either side

Machine Specifications

Download the Simmons WTC-250 Wheel Turning Center product data sheet — for the full machine specification, please contact the Machine Sales team.

Length

3630 mm

Width

2560 mm

Height

2900 mm

Weight

18000 kg

X Axis Travel

1400 mm

Z Axis Travel

406 mm

Table Range, Fully Automatic (Diameter)

305 mm

Maximum Cutting Diameter

1350 mm

Maximum Cutting Height

300 mm

Maximum Wheel Weight

2500 kg

Maximum Wheel Diameter (Standard Jaws)*

1120 mm

*Other sizes possible with custom jaws

Minimum Wheel Diameter (Standard Jaws)*

710 mm

*Other sizes possible with custom jaws

Electrical Power

138 kW

Air

6.2 bar @ 525 SLPM

We're here to help

The NSH USA Customer Service Center (CSC) is here to support you and your machine. As the original equipment manufacturer (OEM), we are ideally suited to keep your machine productive and operating safely.