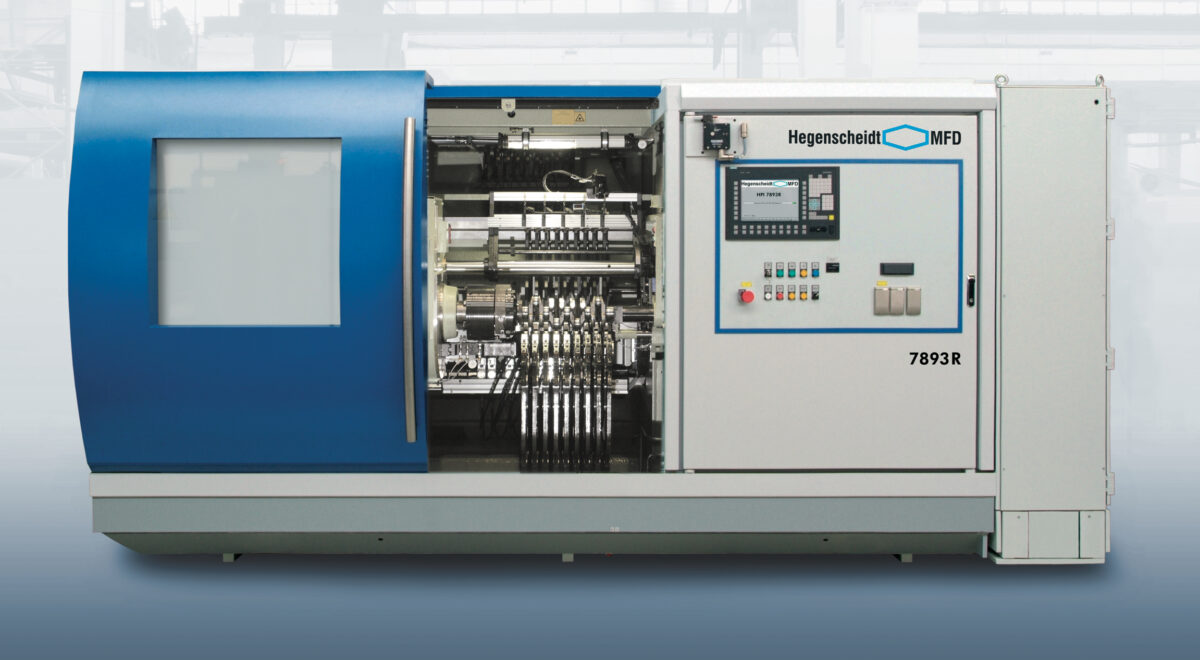

Hegenscheidt Deep Rolling and Straightening Machines

Hegenscheidt-MFD has been at the forefront of deep rolling technology development since its introduction to the automotive industry in 1957.

The crankshaft fillet deep rolling process induces residual compressive stresses into the fillet radii, increasing the fatigue limit and significantly increasing the service life of the work piece. The deep rolling process offers an economical and capable method of optimizing the fatigue strength of high performance crankshafts in high volume production environments.

This technology was perfected by using angle-dependent deep rolling as well as roll-straightening processes. Roll straightening reduces the radial runout present in the crankshaft. Several patents were granted to Hegenscheidt and the NSH Group for the technologies and machine designs introduced between the early development and the levels achieved today. The innovative crankshaft machining technology applied nowadays in the automotive industry for compact motors was pivotal both in achieving material savings and in improving quality and service life.

NSH USA is proud to offer the Hegenscheidt product line for the deep-rolling and roll-straightening of automotive crankshafts to our North American customers – contact us today to find the right machine for your facility.

live video tours and machine introductions

Take a guided walk through our manufacturing facility to see where our machines are manufactured, assembled, and commissioned without leaving your office or home. Check out the machines that are being constructed and tested. Your host will be available to point out specific items of interest as well as answer your questions.

NSH USA invites current and potential customers to book a live video tour!

We're here to help

The NSH USA Customer Service Center (CSC) is here to support you and your machine. As the original equipment manufacturer (OEM), we are ideally suited to keep your machine productive and operating safely.