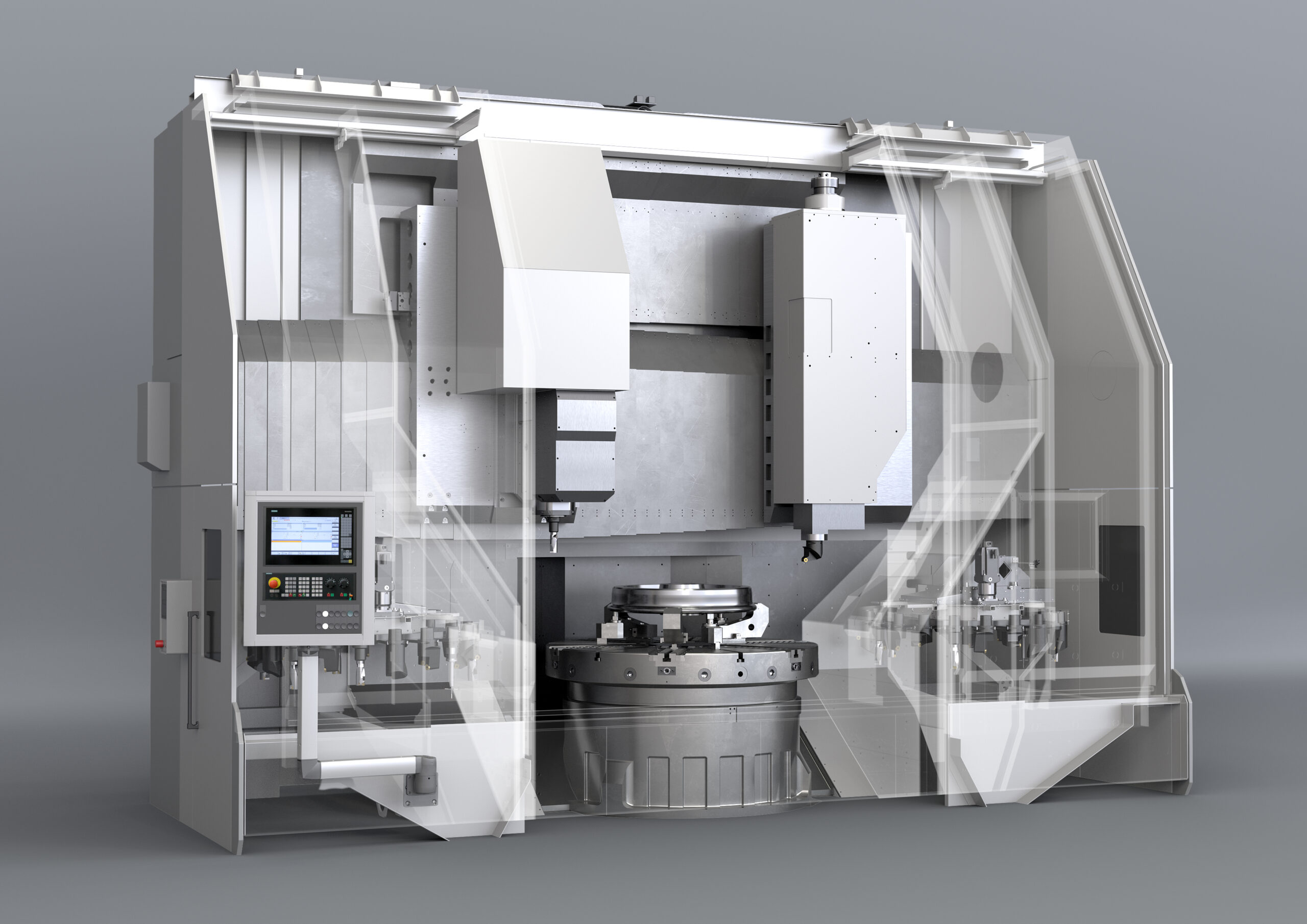

NILES-SIMMONS RQMC Wheel Machining Center

The NILES-SIMMONS RQMC Wheel Machining Centers are CNC vertical machining centers for the heavy duty production of railway wheels. Robust design, use of heavy-duty cutting tools with Capto C10 and HSK 100 interfaces, and automatic tool change ensure optimal machining of forged or hot-rolled wheels.

The RQMC is configured with one turning tool post and one turn-milling head for complete wheel machining. The multi-technology system can also accommodate the machining of rotationally symmetric workpieces from aerospace and bearing industries.

Machine Benefits

These machines offer numerous benefits including:

Roughing and finishing combined in one machine

Automatic tool changer with maximum 20 pocket tool magazine per tool post

Simultaneous tool change into tool magazine during machining time possible

Capto C10 / HSK100 tool interface for long service life

Intuitive control system utilizing Siemens 840 Dsl Operate

Configured for fully automatic work piece loading and unloading

Machine Specifications

Download our NILES-SIMMONS RQMC Wheel Machining Centers product data sheet — for the full machine specification, please contact the Machine Sales team.

Maximum Swing Diameter

1900 mm

Maximum Work Piece Diameter

1600 mm

Clamping Diameter (Range)

520-1500 mm

Clamping Stroke

82 mm

Maximum Work Piece Weight

2000 kg

RQ Maximum Drive Power

120 kW

Speed Range

1-400 rpm

Maximum Torque

22.9 kNm

Rapid Feed

24 m/min

Maximum LH Cutting Force

10 kN

Maximum RH Cutting Force

30 kN

Maximum Slide Travel (Z-Axis)

1000 mm

Maximum Slide Range (X-Axis)

1325 mm

Maximum Slide Range (LH X-Axis)

1435 mm

LH Spindle Speed Range

0-5000 rpm

Maximum Spindle Drive Power

30.5 kW

We're here to help

The NSH USA Customer Service Center (CSC) is here to support you and your machine. As the original equipment manufacturer (OEM), we are ideally suited to keep your machine productive and operating safely.