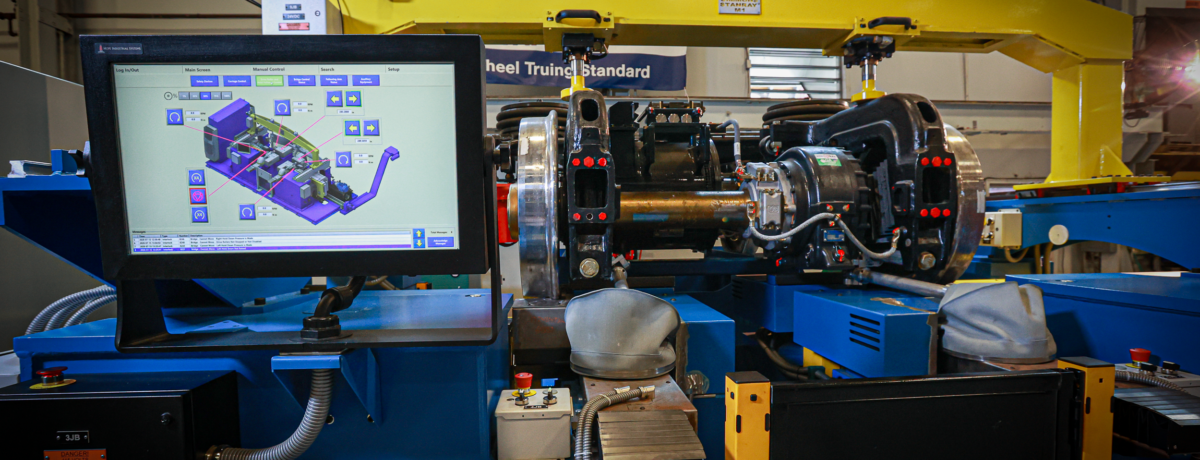

Stanray M1 Above-Floor Wheel Truing Machine

The Stanray® M1 is an above-floor railway wheel truing machine for restoring worn wheel profiles on individual wheel sets or complete bogie assemblies. Utilizing proven Stanray wheel profile milling technology, the M1 performs fully automatic measuring and cutting cycles while managing extreme wheel wear conditions. The machine’s centerless operation allows for simplified construction that requires no pit or special foundation, making it an economical choice.

The Stanray M1 includes an integrated automatic measuring system that monitors the wheel location and measures diameter, width, and profile as well as wheel set back-to-back, back face runout, and radial runout on the tread. Final diameters, profile conformity, and other desired parameters are verified and sent to the customer’s data management system or stored locally. The connectivity of the machine also allows for optional remote diagnostics, which will keep your revenue vehicles safe and on track.

Machine Specifications

Download the Stanray M1 Above-Floor Wheel Truing Machine product data sheet — for the full machine specification, please contact the Machine Sales team.

Cycle Time

Cycle time study available upon request

Profile Accuracy

0.2 mm

Diameter Parity

0.15 mm

Roundness (Radial T.I.R.)

0.1 mm

Surface Finish (as Machined)

< 5 μm Ra

Maximum Electrical Power

70 kW

Maximum Compressed Air

80-100 psi @ 15 scfm

Maximum Wheel Set Weight (= 1⁄2 of bogie)

6804 kg

Maximum Wheel Diameter (at Tapeline)

1118 mm

Minimum Wheel Diameter (at Tapeline)

432 mm

Maximum Wheel Width

148.6 mm

Minimum Bogie Clearance (Lowest Point Above Rail)

50 mm

We're here to help

The NSH USA Customer Service Center (CSC) is here to support you and your machine. As the original equipment manufacturer (OEM), we are ideally suited to keep your machine productive and operating safely.