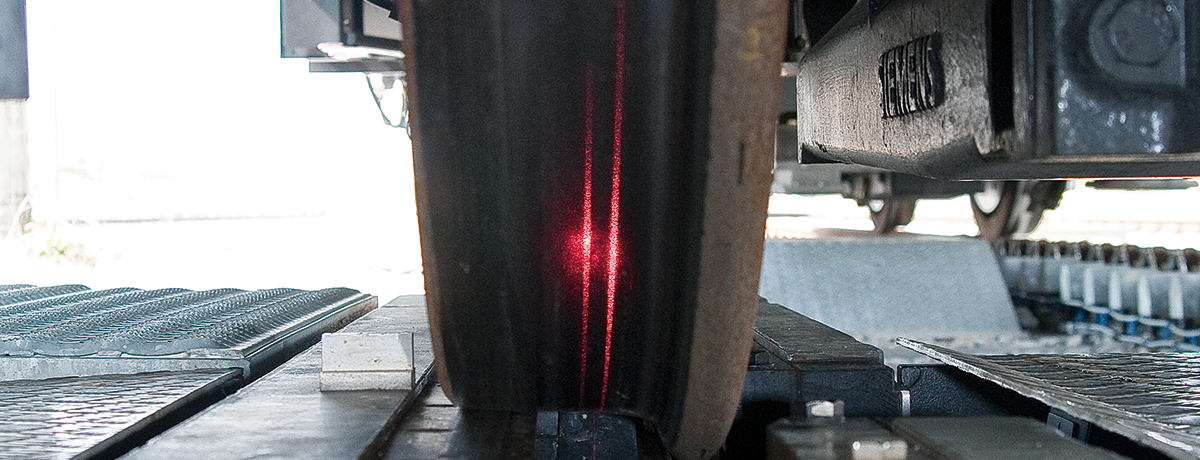

Hegenscheidt ARGUS II Wheel Set Inspection System

The Hegenscheidt ARGUS II Wheel Set Inspection System is a development of the Hegenscheidt ARGUS inspection and testing technology. Now for the first time, in addition to the diagnosis of railway vehicle wheel sets, it can also carry out the diagnosis of tram wheel sets in drive through operation.

Thanks to the new design, the system is installed without a foundation, considerably reducing the installation time and the associated costs. The rail intended as the site of installation can be converted into the test rail within one day, so ensuring that the track is returned to service “in days” rather than “in weeks”. A fully-automated process identifies and measures vehicles when they enter the measuring section. All relevant measurement data are archived in a database. The operator can thus monitor his fleet of wheel sets on a continuous basis with no personnel costs or loss of time. On the basis of the collected measurements, it is possible to determine a wear characteristic, which can provide the basis for a maintenance program that is economically oriented as well as environmentally and safety-conscious.

Benefits

Machine Specifications

Download our Hegenscheidt ARGUS II Wheel Set Inspection System product data sheet — for the full machine specification, please contact the Machine Sales team.

Track gauge

1.435 mm*

*or according to customer requirements

Wheel back distance

Nominal size ±5 mm

Maximum axle distance in bogie

1.300 mm

Maximum axle load

250 kN

Measuring area measuring circle diameter

700 – 1.300 mm*

*or according to customer requirements

Passing speed

max. 30 km/h

Measurement passage speed

3 bis 15 km/h

Speed fluctuation during measurement

±10 %

Length of system

Approx. 15.000 mm*

*or according to customer requirements

Width of all modules

Approx. 2.500 mm*

*or according to customer requirements

Width basis unit/measuring container

Approx. 4.500 mm*

*or according to customer requirements

Rail forerun and after-run

Approx. 25 m

Train units (=70 wheel sets)

Approx. 1 min

Time between 2 measurements

Approx. 5 min

Designed in acc. with VDE, EN and EC specifications.

(customer electrical reguations are taken into account after confirmation)

Power supply

400 V* 50 Hz + 6%-10%

Total power input

Max. 30 kVA

Mains configuration

TN

Driving power feedback

Customer supplied

We're here to help

The NSH USA Customer Service Center (CSC) is here to support you and your machine. As the original equipment manufacturer (OEM), we are ideally suited to keep your machine productive and operating safely.