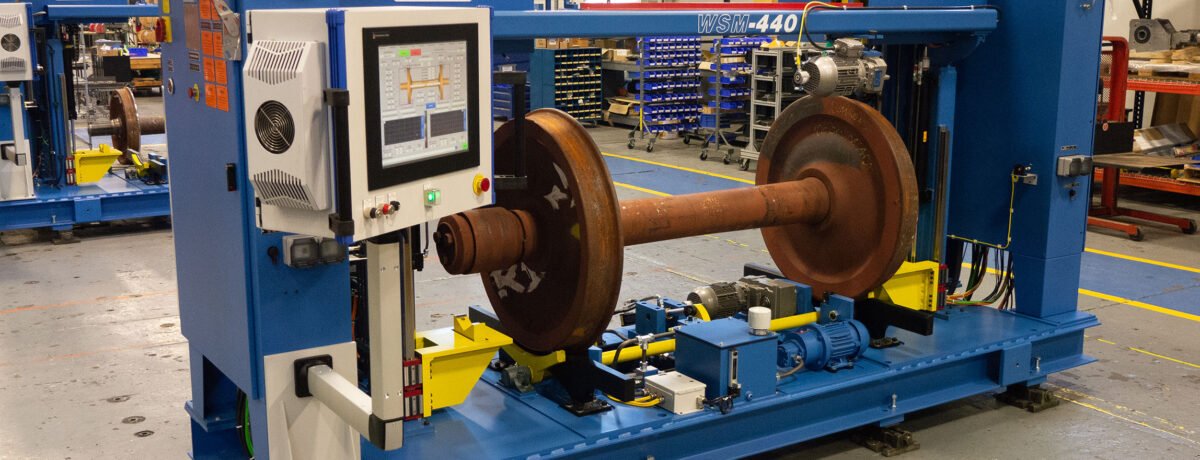

Simmons WSM-440 Wheel Set Measurement System

The Simmons WSM-440 Wheel Set Measurement System is a metrology machine that automatically inspects new or reconditioned railroad wheel sets. The WSM-440 measures wheel diameter and width, flange thickness and height, wheel rim thickness, profile deviation, back-to-back, and radial and axial wheel tread runout. Measurements are stored in a local database at the machine or can be networked to transfer the data to a remote server. If interfaced with a facility supervision system, those measurements can be used to automatically route the wheel set for maintenance.

Wheel sets are delivered to the WSM-440 via shop rails and once captured, the measuring heads are automatically positioned against each wheel tread. The wheel set is rotated while the wheel profiles are measured. The contact probes are fitted with linear gauges in the measuring arms. The measurement results for both wheels will be displayed on local HMI and saved to the database. The control system determines if the wheel set conforms to the predefined geometry for that particular wheel set type.

Machine Specifications

Download the Simmons WSM-440 Wheel Set Measurement System product data sheet — for the full machine specification, please contact the Machine Sales team.

Wheel Diameter

+/- 0.13 mm

Flange Thickness

+/- 0.3 mm

Flange Height

+/- 0.3 mm

Rim Thickness

+/- 0.5 mm

Wheel Back-To-Back

+/- 0.25 mm

Wheel Profile Deviation

+/- 0.2 mm

Wheel Width

+/- 0.5 mm

Radial Runout at Tapeline on Centers

+/- 0.05 mm

Plane Runout

+/- 0.3 mm

*Applicable up to maximum ambient temperature change of +/-10°C

Electrical Power Requirement

27.5 kW

Compressed Air

15 scfm @ 80 psi

Maximum Wheel Diameter

1067 mm

Minimum Wheel Diameter

711 mm

Maximum Axle Length

2286 mm

Maximum Weight

1820 Kg

We're here to help

The NSH USA Customer Service Center (CSC) is here to support you and your machine. As the original equipment manufacturer (OEM), we are ideally suited to keep your machine productive and operating safely.