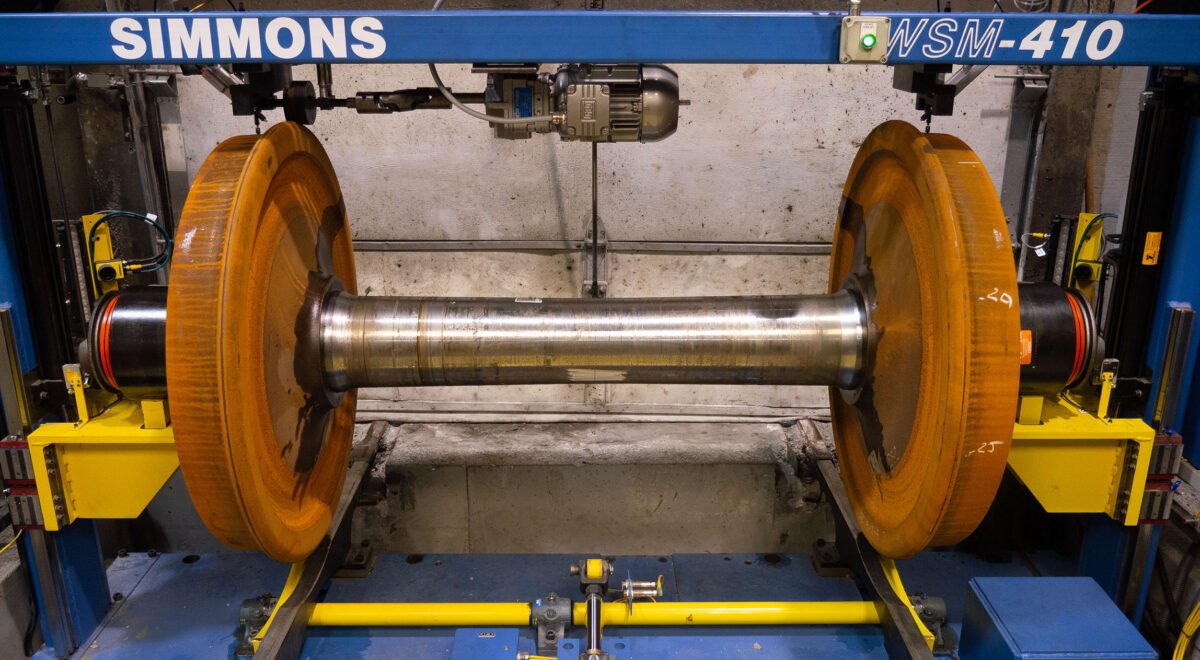

Simmons WSM-410 Wheel Set Runout and Inspection Station

The Simmons WSM-410 Wheel Set Runout and Inspection Station automatically inspects new and re-machined railway wheel sets with outboard bearings to determine if the wheel runout relative to the bearings is acceptable.

This machine lifts and supports the wheel set by the bearings or bearing journals, in accordance with AAR or other requirements. After the wheel set is cradled and lifted, the wheel set is spun and measuring probes automatically determine if the plane and radial runout measurements meet the predetermined requirements. The machine is also available with optional back-to-back measurement capability as well as bent tab verification cameras to identify any unbent tabs on the axle end locking plates.

The handling of the wheel set after measurement is configured to accommodate the wheel set maintenance facility where it is installed. For example, if the wheel set passes inspection, it will automatically be lowered and ejected from the station onto rails for manual handling. If the wheel set fails this inspection, it can display an alarm and hold the wheel set in the machine until an operator manually inspects and releases the wheel set. The machine can also be interfaced with an automated material handling system. The results of the measurements are sent along with the wheel set to the material handling system for proper routing.

Machine Specifications

Download the Simmons WSM-410 Wheel Set Runout And Inspection Station product data sheet — for the full machine specification, please contact the Machine Sales team.

Cycle Time

2 minutes

Plane Runout Accuracy and Repeatability

+/- 0.05 mm

Radial Runout Accuracy and Repeatability

+/- 0.05 mm

Back-To-Back Accuracy (optional)

+/- 0.1 mm

Back-To-Back Repeatability (optional)

+/- 0.05 mm

*Applicable up to maximum ambient temperature change of +/-10°C

Electrical Power Requirement

6.4 kW

Compressed Air (Minimal Volume Required)

5.5-8.3 bar

Maximum Wheel Diameter

1067 mm

Minimum Wheel Diameter

711 mm

Maximum Axle Length

2286 mm

We're here to help

The NSH USA Customer Service Center (CSC) is here to support you and your machine. As the original equipment manufacturer (OEM), we are ideally suited to keep your machine productive and operating safely.