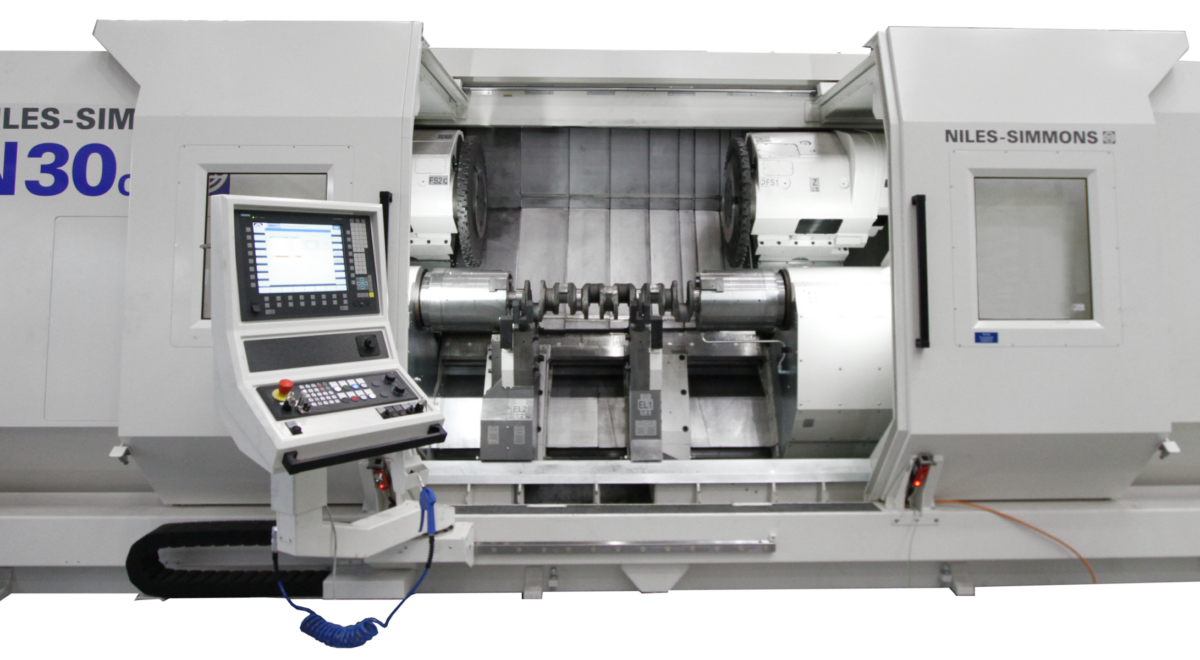

NILES-SIMMONS CM-Series Crankshaft/Camshaft Milling Centers

The NILES-SIMMONS CM-Series Crankshaft/Camshaft Milling Centers perform rough and finish milling of the main and pin bearing journals on automotive truck and passenger vehicle crankshafts. Based on the modularity of the proven N-Series lathes, the machines accommodate crankshafts up to 1800 mm in length, and camshafts and eccentric shafts up to 2400 mm.

Symmetrical work spindles are driven by gearless torque motors and are synchronized electronically. For this process, the work spindles are equipped with optimized bearings. Axial and cross slides are guided by a combination of box and anti-friction roller guideways.

Two compact milling units, each with powerful synchronous drives, ensure simultaneous dry milling of crankshafts in one concentric setup. Up to two NC-positioned steadyrests provide customized clamping solutions with integral or separate radial orientation of work pieces. In addition to the standard milling processes, the CM-Series machines also implement hard milling technology, which substitutes the pre-grinding of hardened crankshafts.

Contact NSH USA today to learn more about these precision crankshaft machining centers.

live video tours and machine introductions

Take a guided walk through our manufacturing facility to see where our machines are manufactured, assembled, and commissioned without leaving your office or home. Check out the machines that are being constructed and tested. Your host will be available to point out specific items of interest as well as answer your questions.

NSH USA invites current and potential customers to book a live video tour!

We're here to help

The NSH USA Customer Service Center (CSC) is here to support you and your machine. As the original equipment manufacturer (OEM), we are ideally suited to keep your machine productive and operating safely.