Product Development: Wheel Boring Integrated Measurement

Simmons’ commitment to accurate and precise wheel set measurement in the railway wheel shop environment is well documented. Measurement data that is free of operator error leads to more efficient and safe wheel set maintenance and production practices.

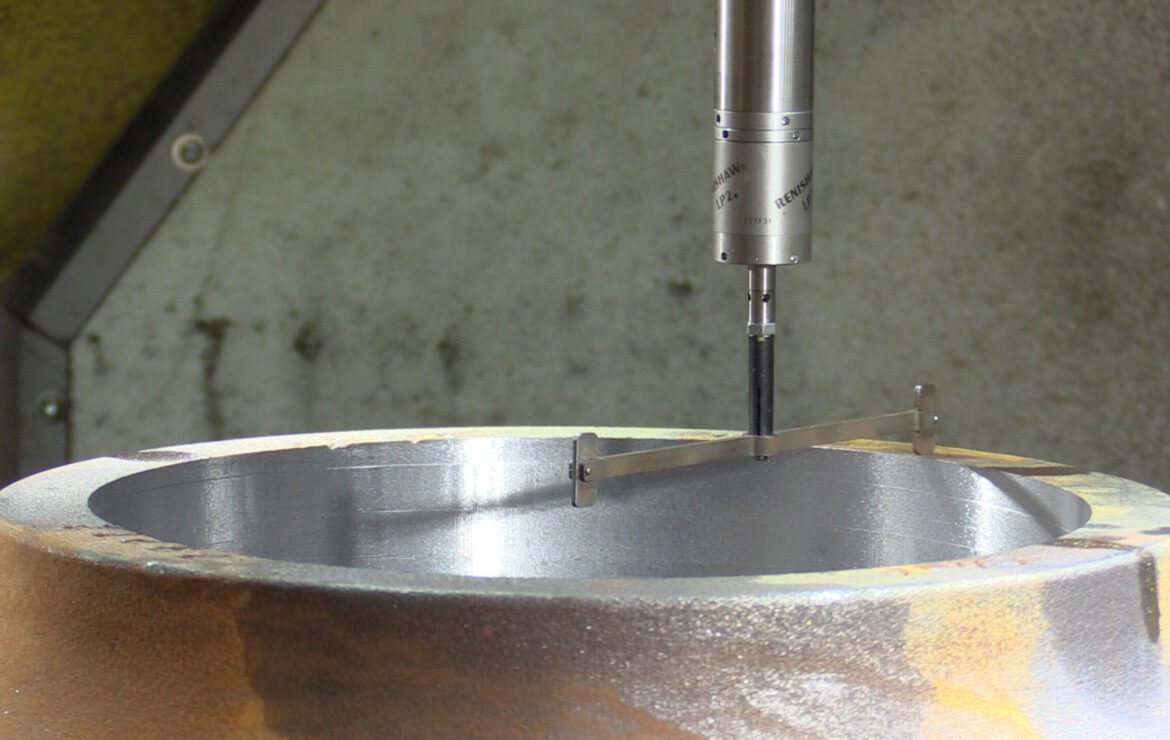

With that in mind, we designed the new WTC-250 Wheel Turning Center with integrated measurement. The measuring probe collects pre- and post-machining wheel data for superior workpiece qualification. Consistent bore and taper measurements means improved compliance with AAR standards. This data can also decrease the wheel press‘ misfit ratio, which produces safer wheel sets and less scrapped wheels and axles. Increased access to pre- and post-machining data allows the facility to observe trends and better manage manufacturing goals and preventive maintenance programs.

Integrated wheel bore measurement is just one of the design innovations included in the WTC-250. Watch this space for more product development news in the coming weeks.