Product Development: The Stanray M-Series’ Updated Cutter Body Design

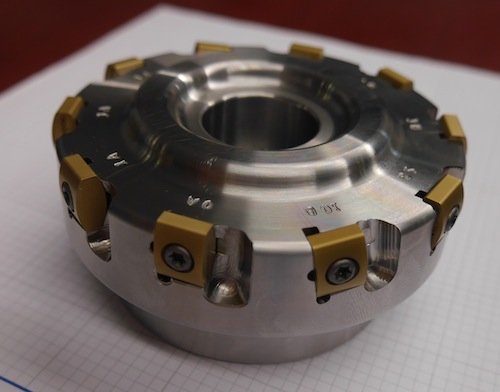

The Stanray® TN-84C Underfloor Wheel Truing Machine‘s milling cutter body design has been through surprisingly few changes since its first iteration in 1949. The cutter body, which holds multiple cutting inserts, rotates rapidly while the workpiece (in this case, a wheel) rotates slowly.

The original design consisted of 10 removable blades, each holding 11 carbide cutting inserts. There was a short iteration that had 16 blades with taper adapter. The current design for the TN-84C’s cutter body has 13 blades.

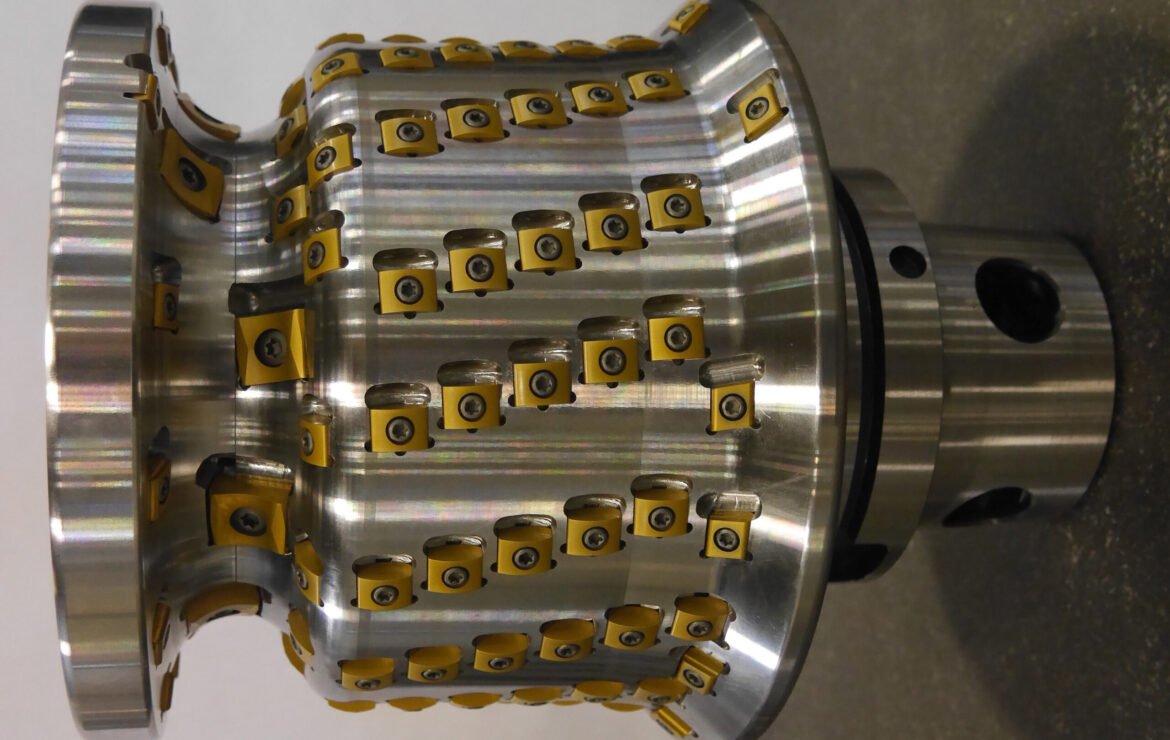

The new Stanray M-Series Wheel Truing Machines features game-changing updates to the cutter body design in the following ways:

- Easier wheel profile exchange: the current cutter body assemblies weigh nearly 300 lbs. and can take an hour or more to exchange. The new cutter bodies are smaller, 60% lighter, and utilize an extremely rigid quick change coupling. Switching to another wheel profile will now take a few minutes.

- Extended tool life: the new design does away with the blades and places the indexable carbide cutting inserts directly onto the cutter body. This creates a stiffer, stronger interface, extending insert life due to less vibration.

- Increased productivity: the new design has two effective flutes, which means twice as much material per revolution is removed compared to the current design.

- Better surface finish: enhanced insert geometry as well as modern computer solid modeling lay-out tools produce a superior wheel surface finish.

What has not changed is the Stanray’s proven full-profile milling process, which has managed extreme wheel wear conditions in facilities worldwide for several decades.