Wheel Set and Bearing Presses

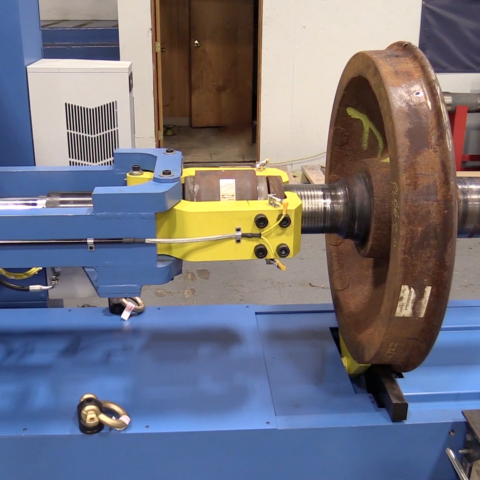

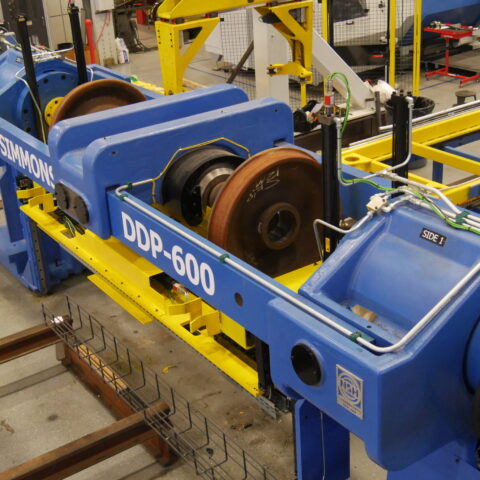

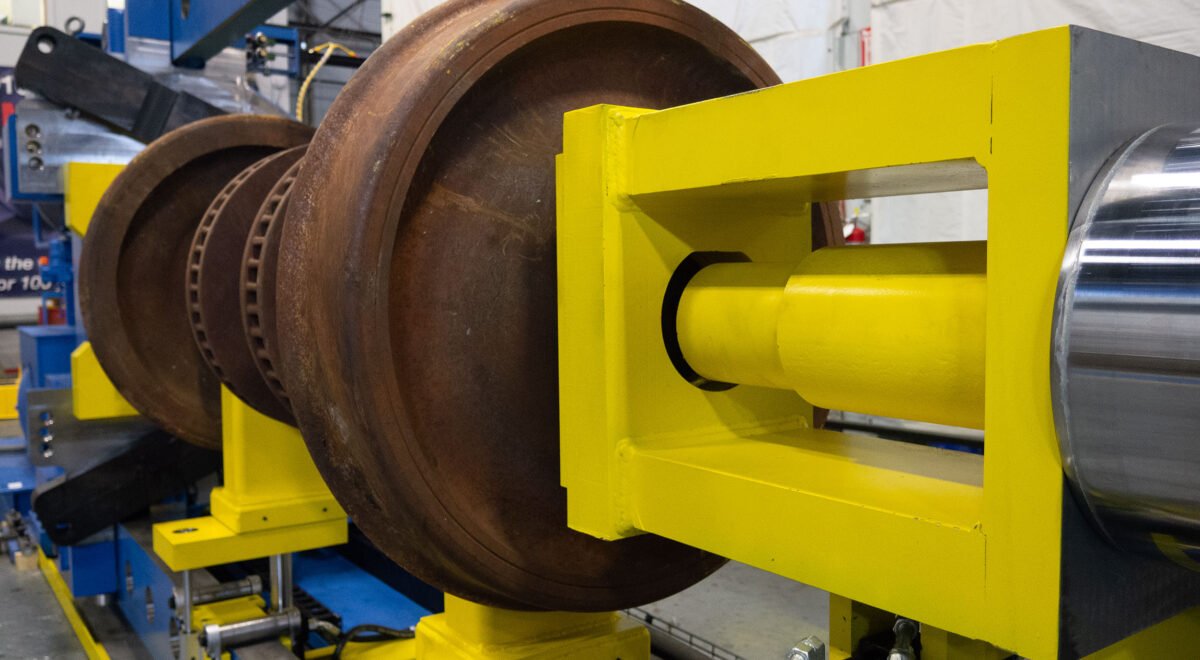

NSH USA Corporation offers a full line of Simmons railway wheel and bearing presses for the mounting and demounting of wheel set components. Wheel set maintenance and production facilities around the world depend on these robust and dependable machines.

Wheel set maintenance and production facilities around the world depend on these robust and dependable machines. The presses are designed to operate in conjunction with our other wheel shop equipment for automated control of the mounting graph. Total machine integration provides real-time process control of the wheel mounting graph by managing the cutting tools of the wheel boring machine and ensuring proper lubrication of the wheel bore and axle wheel seat. This “closed loop” process greatly decreases the misfit ratio during mounting cycles, increasing production and efficiency.

The presses can also be operated as stand-alone systems for mounting and demounting, handling a wide range of wheel set components. The machines are configured to meet the production goals of the wheel set maintenance facility.

The mounting presses include an electronic Press Recorder, which produces a pressure diagram, reflecting tonnage over distance. The tonnage recorder stores the pertinent wheel and axle data such as wheel and axle serial numbers, mount number, and misfit causes, allowing the stored data to be saved and accessed at the station or transferred to a central computer and/or printer.

live video tours and machine introductions

Take a guided walk through our manufacturing facility to see where our machines are manufactured, assembled, and commissioned without leaving your office or home. Check out the machines that are being constructed and tested. Your host will be available to point out specific items of interest as well as answer your questions.

NSH USA invites current and potential customers to book a live video tour!

We're here to help

The NSH USA Customer Service Center (CSC) is here to support you and your machine. As the original equipment manufacturer (OEM), we are ideally suited to keep your machine productive and operating safely.